Revolutionizing Warehouse Operations: Palmary’s Leap into Digital Transformation

Enhancing efficiency and accuracy in every aisle of Palmary's warehouse

Project overview

The Warehouse Management System (WMS) project aims to transform and optimize the operations of a warehouse by implementing a comprehensive digital solution. This project involves designing and deploying a robust WMS and Mobile App for operators that integrate seamlessly with existing business processes to improve efficiency, accuracy, scalability, and DLC management

Timeline

June 2024 - Till Now (Support)

Client

Palmary

Team Members

- Project manager

- CTO

- 4 Full stack developers

- 2 UX/UI Designer

- 2 QA

Objectives

Enhance operational efficiency

Automate and streamline warehouse operations such as inventory tracking, order fulfillment, and goods reception & putaway, reducing manual errors and improving processing speed.

Improve inventory accuracy

Implement real-time tracking and management of inventory to ensure stock levels are accurate, reducing the risk of stockouts and overstock situations.

Optimize space utilization

Apply intelligent algorithms to determine optimal storage locations, maximizing warehouse space efficiency while considering storage constraints and product expiration dates (DLC).

Key Features

User and role management

A secure system with role-specific access controls, ensuring that users operate within their designated permissions for security and operational integrity.

Product management

Comprehensive product catalog setup, including SKU management and logistical details.

Multi-storage type management

Handle diverse storage types, including bulk storage (stock en masse) and rack storage, with flexible configuration options to optimize space, facilitate organization, and improve accessibility.

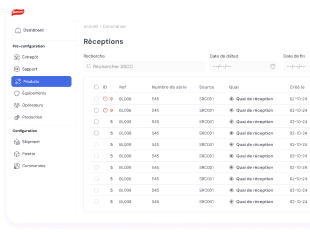

Receiving and shipping

Automated processes for goods reception and shipping, utilizing barcode/RFID scanning for swift and accurate data entry.

Order processing

Efficient order management, including creation, tracking, and fulfillment of both global and route-specific orders.

Stock replenishment and transfers

Automated replenishment tasks and support for manual stock transfers, ensuring optimal stock levels.

Returns management

Streamlined handling of product returns, integrating seamlessly with the inventory system.

Pain Points

Palmary faced significant issues in managing high volumes of inventory, resulting in frequent order inaccuracies, inefficient stock placement, and high operational costs.

Challenges During Implementation

Data integration

Integrating existing data from various sources into the new WMS posed a significant challenge, requiring careful mapping and conversion processes.

Master data acquisition & management

Ensuring accurate and up-to-date master data was challenging due to frequent changes and the continuous addition of new products.

User adoption

Ensuring seamless transition and user adoption among warehouse staff who were accustomed to manual processes.

System customization

The need for specific customizations to accommodate Palmary’s unique warehouse operations and workflow requirements.

Solutions

Comprehensive data mapping

Detailed planning and execution of data integration processes ensured a smooth transition of product and operational data into the WMS.

Training programs

Conducted extensive training sessions for warehouse personnel, focusing on new processes and the use of PDAs to streamline operations.

Tailored system customizations

Developed specific custom features within the WMS to align with Palmary's operational needs and improve overall workflow efficiency.

Tech Stack & Integrations

1Frontend

- Vue.js:A progressive JavaScript framework used to build the user interface.

- Quasar: A high-performance Vue.js framework for building responsive websites and mobile apps.

- Tailwind CSS:A utility-first CSS framework for custom styling of the frontend.

2Mobile App

- Webview: Used to wrap the web-based frontend for mobile app experience.

- Kotlin: The primary language for Android app development.

- Bluetooth Manipulation: Functionality integrated for managing Bluetooth connections directly from the app.

3Backend

- Laravel: A PHP framework for building the backend with expressive and elegant syntax.

- FilamentPHP: A lightweight admin panel for Laravel, used to manage the backend and ease developer workflow.

4Database

- MySQL: A relational database management system used to store the app’s data.

5Cloud Services / Infrastructure ( Used for Local Deployment)

- AWS (Amazon Web Services): Cloud infrastructure used for hosting and scalability (if applicable).

- Nginx: A high-performance web server and reverse proxy (used for local deployments).

- Laravel Forge: A tool used to provision and deploy Laravel applications, even on local client servers (used for local deployment setup).

6Infrastructure Hosting

- Client Servers: The application is deployed on servers located at client warehouses.

- Local Infrastructure: The servers are maintained and managed by the client on their premises, but configured and managed using tools like Forge and Nginx.

7Integrations

- rsync: A tool for synchronizing files and directories across remote and local servers.

- Industrial printers: Integration with specialized printers for industrial use, such as printing labels, receipts, etc.

Results

Enhanced efficiency

Achieved a huge reduction in manual processing times, significantly improving overall operational efficiency.

Improved accuracy

Order and stock accuracy improved, reducing discrepancies and enhancing reliability.

Faster order fulfillment

Order processing times were reduced, leading to quicker deliveries and improved customer satisfaction.

Cost savings

Operational costs decreased, marking a substantial improvement in cost management.